International Terminal, Houston, TX, USA

Further information and case study for this project can be found at the De Gruyter Birkhäuser Modern Construction Online database

The following architectural theory-based case study is not available at Modern Construction Online

Houston International Airport Terminal — Integrating Structured Flow and Symbolic Public Space

The Houston International Airport Terminal, designed and engineered by Newtecnic for regional air traffic, exemplifies how contemporary infrastructure can simultaneously function as a logistical system and a symbolic public space. Organised around structured flow systems, the terminal utilises parametric design tools and digitally coordinated fixing strategies to deliver high-performance spatial and environmental outcomes.

This case study resonates with the themes explored in Modern Construction Handbook, Modern Construction Envelopes, and Modern Construction Case Studies (Watts, 2016, 2019a, 2019b, 2023), in which envelope performance, structural clarity, and adaptable fixing systems are central mediators between architectural form and function. The terminal’s tectonic articulation and operational precision are the result of a fully integrated file-to-factory design methodology, embodying the principles of performance-led architecture.

Historically, the project aligns with the High Modernist ambition to merge infrastructure with civic identity. Precedents such as Eero Saarinen’s TWA Flight Center (1962), Le Corbusier’s Palace of the Soviets (1931–1933, unbuilt), and Kenzo Tange’s Yoyogi National Gymnasium (1964) serve as critical reference points—each redefining infrastructure as cultural artifact through expressive form and innovative engineering. These principles are reinterpreted in the Houston Terminal through digital design and precision-fabricated tectonics.

Precedent-Informed Strategy from Modern Environmental Design

Project 08 builds upon the long-term environmental strategy outlined in Project 13 of Modern Environmental Design (Watts, 2022a), which emphasises low-impact maintenance and occupant comfort throughout the building lifecycle. Maintenance infrastructure—including roof-mounted cleaning rails and service-access walkways—is integrated into the structural framework to allow safe, non-disruptive interventions without large equipment or operational downtime.

Circulation and servicing zones align with opaque structural panels to optimise internal spatial efficiency. Shading elements serve dual purposes, operating both as environmental devices and maintenance platforms. This integrative strategy supports a holistic model of sustainable lifecycle management, minimising energy use and facilitating phased servicing without disturbing primary operations.

Facade Technology and the Influence of Galaxy Soho

The terminal’s façade design draws clear inspiration from the envelope systems developed for Galaxy Soho, Beijing, as documented in Modern Construction Case Studies (Watts, 2016). Galaxy Soho’s fluid geometry challenged conventional panelisation, pioneering bespoke aluminium subframes and bracket systems to maintain surface continuity over complex curves.

The Houston Terminal applies this methodology through a high-performance envelope system comprising unitised glazing and pin-jointed aluminium brackets that accommodate thermal movement and structural shifts without compromising module clarity. Installation and maintenance are streamlined through digitally coordinated, tool-less systems informed by BIM workflows and CNC fabrication techniques.

Thermal performance and solar modulation are enhanced through fritted glazing, precision-engineered thermal breaks, and articulated motorised sunshades. This digitally fabricated envelope reconciles symbolic form with environmental and logistical demands, positioning the project within a lineage of technologically sophisticated, performative façade design.

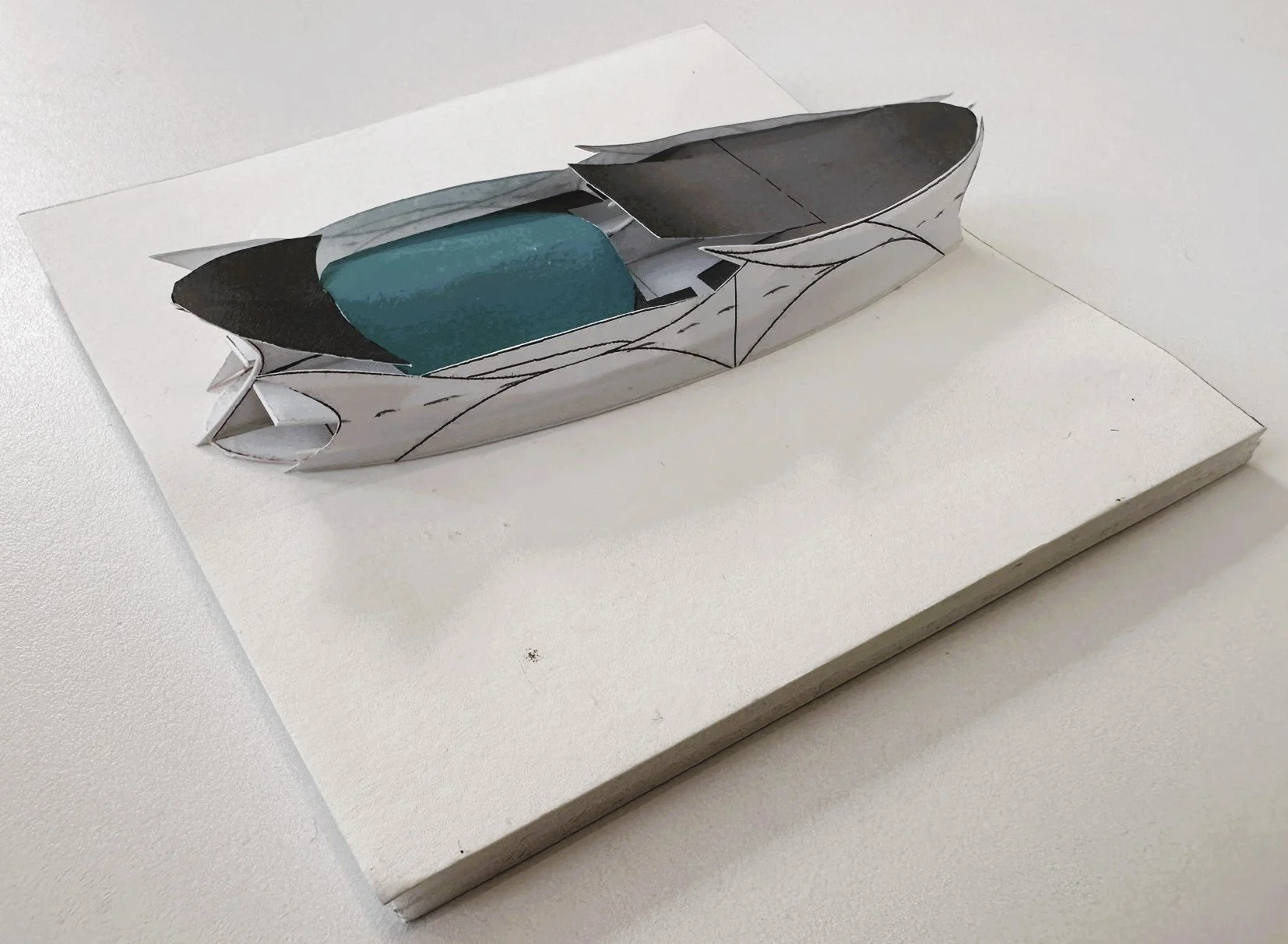

Spatial Organisation and Circulatory Flow

The spatial layout adopts a tripartite vertical organisation: subterranean infrastructure, ground-level processing, and elevated departure volumes. Echoing the rational spatial strategies identified by Heynen (1999), this zoning optimises spatial hierarchy and operational clarity.

Subterranean tunnels are constructed from precast concrete box modules, integrated with T-slot aluminium fixing rails that support tool-less retrofitting of lighting, cable trays, and environmental services. Interior tunnel linings use removable aluminium panels with concealed Z-clip brackets for rapid MEP access.

Aircraft stands extend peripherally from the terminal body, enhancing airside logistics. Prefabricated jet bridges and apron canopies are fixed with telescopic steel plates engineered to absorb thermal expansion and ground movement—detailing approaches consistent with those in Modern Construction Envelopes (Watts, 2019b).

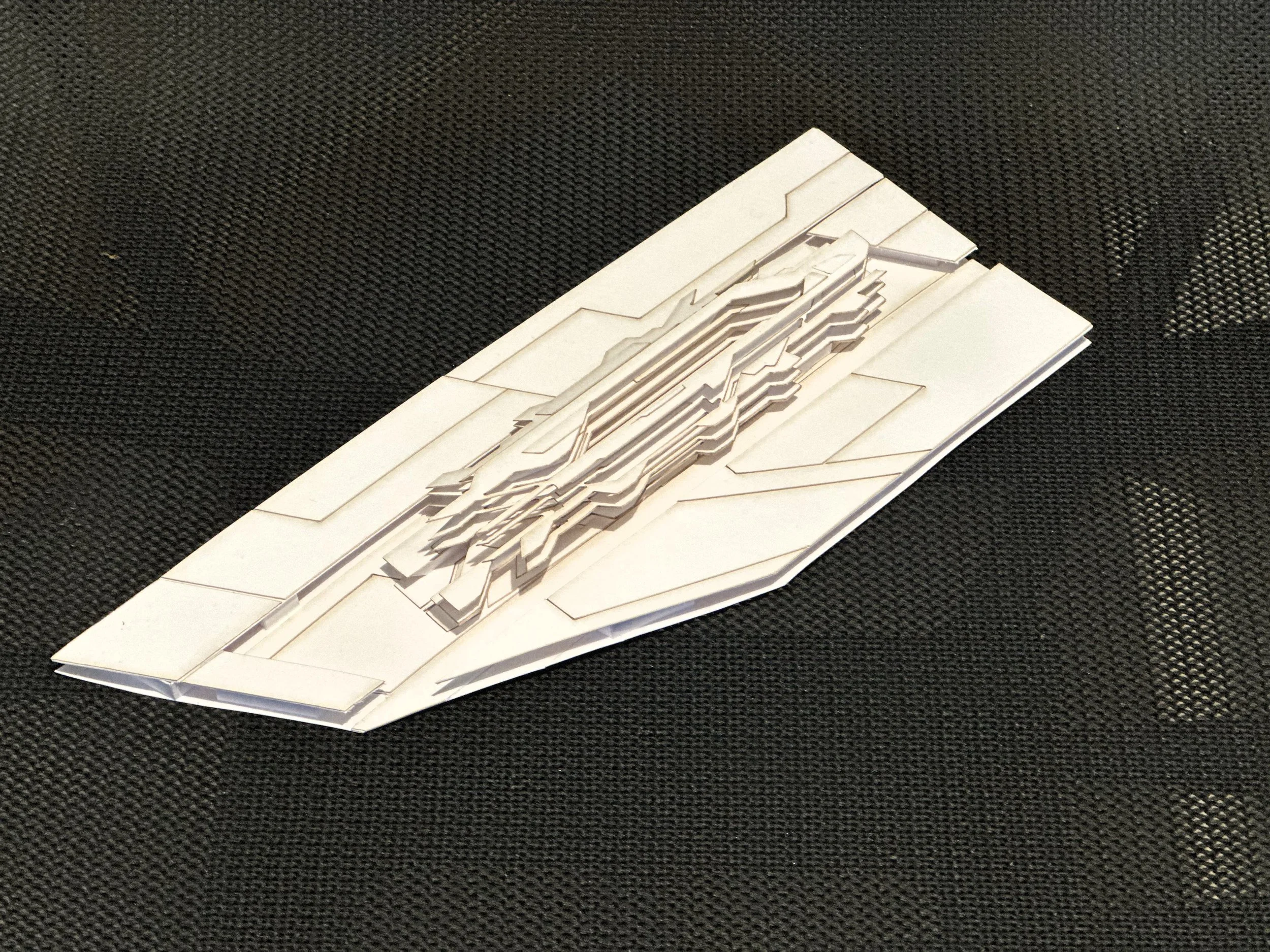

Architectural Form and Structural Logic

The architectural expression is defined by interlocking volumes framed with prefabricated steel space frames joined using bolted spherical node connectors. This dry-assembly system accelerates erection, improves precision, and reduces on-site welding, maintaining geometric legibility and structural integrity.

Curtain walls composed of unitised glazing panels are installed on pin-jointed aluminium brackets that align with the primary structural rhythm while allowing differential movement. Parametric solar modelling guides glass fritting, orientation, and module dimensions, optimising daylighting and glare control—techniques elaborated in Modern Construction Handbook (Watts, 2023).

Ceiling baffles and daylight modulation systems are suspended from the primary frame using clevis-connected cable assemblies. Anchor placements are determined via total station laser mapping, ensuring millimetre-level precision in alignment and light distribution.

Envelope Logic and Environmental Performance

Functioning as both environmental enclosure and symbolic surface, the envelope integrates airtightness, thermal control, and expressive detailing. Strip fenestration uses unitised, thermally broken glazing systems clipped onto a cold-formed aluminium substructure. RFID-tagged components enable sequenced, top-down installation that preserves the envelope's continuous airtight layer.

Opaque areas are clad in insulated metal cassettes with concealed brackets and gasketed joints, engineered to eliminate thermal bridging. Their placement is informed by seasonal daylight simulations, aligning environmental performance with architectural composition.

Motorised sunshades on solar-intensive elevations are mounted via articulated bracket arms, concealing motors and services while enabling dynamic solar control via the BMS. Zero-gap shadow reveals between envelope modules—developed through CNC prototyping—express technical sophistication and formal clarity, central to contemporary façade detailing (Watts, 2019b, 2023).

Parametric Fabrication and Fixing Systems Integration

All building elements are coordinated via a parametric BIM model linking spatial data to fabrication and assembly specifications. Aluminium modules are cold-formed with CNC-drilled fixing nodes, and roof purlins are connected with slotted, laser-cut plates engineered for seismic resilience and load path redundancy.

Interior partitions, signage, and MEP systems are supported by concealed Unistrut channels embedded in cavity walls, facilitating flexible reconfiguration. This method—highlighted in Modern Construction Case Studies (Watts, 2019a)—supports both long-term adaptability and surface coherence.

Digital workflows support just-in-time delivery, RFID-based logistics, and lifecycle traceability. Each fixing, bracket, and joint is part of a unified assembly logic that merges spatial order with performance-driven design.

Conclusion

The Houston International Airport Terminal embodies a contemporary vision of infrastructural architecture—merging logistical efficiency, symbolic form, and digital precision. Parametric spatial zoning, responsive envelope systems, and integrated fixing strategies reframe High Modernist planning within a digitally enabled construction context.

Designed by Newtecnic, the terminal exemplifies how lifecycle-aware, data-driven design can elevate infrastructure beyond utility into a coherent architectural expression. As articulated in the works of Watts (2016, 2019a, 2019b, 2022a, 2023), every fixing bracket and cladding seam becomes both technical element and architectural gesture—realising a hybrid architecture of performance, clarity, and adaptability.

References

Addington, M. and Schodek, D., 2005. Smart Materials and New Technologies for the Architecture and Design Professions. Oxford: Architectural Press.

Borden, I. and Rendell, J., 2000. Intersections: Architectural Histories and Critical Theories. London: Routledge.

Corbusier, Le, 1931–1933. Palace of the Soviets [unbuilt project]. Moscow.

Heynen, H., 1999. Architecture and Modernity: A Critique. Cambridge, MA: MIT Press.

Kolarevic, B., 2003. Architecture in the Digital Age: Design and Manufacturing. New York: Taylor & Francis.

Koolhaas, R., 1995. S, M, L, XL. New York: Monacelli Press.

Saarinen, E., 1962. TWA Flight Center [built work]. New York: Eero Saarinen and Associates.

Tange, K., 1964. Yoyogi National Gymnasium [built work]. Tokyo: Kenzo Tange and URTEC.

Watts, A., 2016. Modern Construction Case Studies. 1st ed. Basel: Birkhäuser.

Watts, A., 2019a. Modern Construction Case Studies. 2nd ed. Basel: Birkhäuser.

Watts, A., 2019b. Modern Construction Envelopes. 3rd ed. Basel: Birkhäuser.

Watts, A., 2022a. Modern Environmental Design. Basel: Birkhäuser.

Watts, A., 2023. Modern Construction Handbook. 6th ed. Basel: Birkhäuser.